The global manufacturing landscape is witnessing a transformative shift in hydraulic tube end forming technology, with servo integration and accelerated cycle times emerging as the defining innovations reshaping productivity and precision. Recent advancements in equipment design are delivering unprecedented performance gains, energy efficiency, and process flexibility, catering to the evolving demands of automotive, aerospace, and industrial sectors worldwide.

At the forefront of this evolution is the seamless integration of servo control systems into hydraulic tube forming machinery, marking a departure from traditional hydraulic setups. These servo-hydraulic hybrid systems combine the high thrust capacity of hydraulic technology—with some units delivering up to 220 kN (22 tons) of force—with the precision and programmability of servo motors. This synergy enables real-time adjustment of pressure, position, and feed rates, ensuring consistent forming quality even for complex geometries and high-strength materials like stainless steel. The result is a significant reduction in dimensional variations, with repeatability enhanced through closed-loop control that adapts to material properties and production requirements dynamically.

Energy efficiency has emerged as a key benefit of servo-integrated designs. By replacing conventional hydraulic systems with servo-driven actuation, modern machines achieve up to 70% energy savings compared to traditional models, while also reducing operational noise by over 40%. These systems minimize energy waste through power delivery, avoiding the constant pressure draw of traditional hydraulics, and operate at lower temperatures—typically between 35°C and 45°C—reducing thermal wear on critical components and extending equipment lifespan.

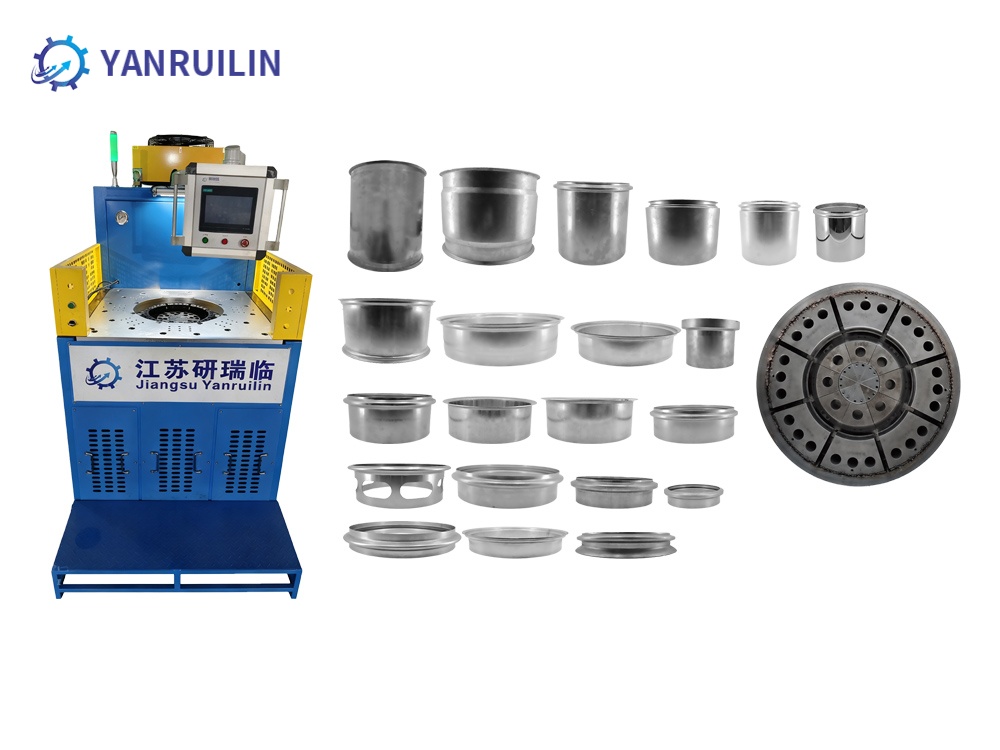

Cycle time optimization has become another cornerstone of innovation, with new machine architectures slashing production times by up to 20% compared to previous generations. A key enabler is the integration of multiple processing stations—some offering up to nine configurable positions—allowing for sequential operations such as tapering, flaring, threading, and chip removal in a single pass. Dual-end forming capabilities further boost efficiency by processing both tube ends simultaneously, eliminating the need for secondary handling. Advanced tooling designs, including quick-change cartridges and CNC-controlled rolling devices, reduce setup times and enable rapid product changeovers, supporting high-volume production of diverse part configurations.

The global manufacturing landscape is witnessing a transformative shift in hydraulic tube end forming technology, with servo integration and accelerated cycle times emerging as the defining innovations reshaping productivity and precision. Recent advancements in equipment design are delivering unprecedented performance gains, energy efficiency, and process flexibility, catering to the evolving demands of automotive, aerospace, and industrial sectors worldwide.

At the forefront of this evolution is the seamless integration of servo control systems into hydraulic tube forming machinery, marking a departure from traditional hydraulic setups. These servo-hydraulic hybrid systems combine the high thrust capacity of hydraulic technology—with some units delivering up to 220 kN (22 tons) of force—with the precision and programmability of servo motors. This synergy enables real-time adjustment of pressure, position, and feed rates, ensuring consistent forming quality even for complex geometries and high-strength materials like stainless steel. The result is a significant reduction in dimensional variations, with repeatability enhanced through closed-loop control that adapts to material properties and production requirements dynamically.

Energy efficiency has emerged as a key benefit of servo-integrated designs. By replacing conventional hydraulic systems with servo-driven actuation, modern machines achieve up to 70% energy savings compared to traditional models, while also reducing operational noise by over 40%. These systems minimize energy waste through power delivery, avoiding the constant pressure draw of traditional hydraulics, and operate at lower temperatures—typically between 35°C and 45°C—reducing thermal wear on critical components and extending equipment lifespan.

Cycle time optimization has become another cornerstone of innovation, with new machine architectures slashing production times by up to 20% compared to previous generations. A key enabler is the integration of multiple processing stations—some offering up to nine configurable positions—allowing for sequential operations such as tapering, flaring, threading, and chip removal in a single pass. Dual-end forming capabilities further boost efficiency by processing both tube ends simultaneously, eliminating the need for secondary handling. Advanced tooling designs, including quick-change cartridges and CNC-controlled rolling devices, reduce setup times and enable rapid product changeovers, supporting high-volume production of diverse part configurations.

यह वेबसाइट यह सुनिश्चित करने के लिए कुकीज़ का उपयोग करती है कि आपको हमारी वेबसाइट पर सर्वोत्तम अनुभव मिले।

टिप्पणी

(0)